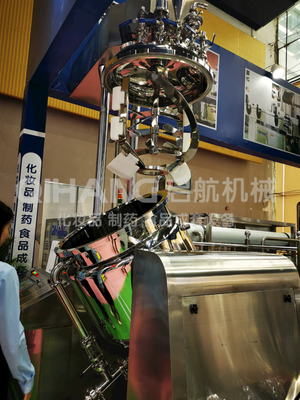

Descrizione di prodotto

2.2KW Daily Supplies Cosmetic Making Machine Toothpaste Shower Gel Lotion Vacuum Emulsifier

Daily Supplies Toothpaste Shower Gel Lotion Vacuum Emulsifier

Description of the Vacuum Emulsifier:

Vacuum emulsifying machine, high shear homogenizer, cosmetic cream mixer means the material in a vacuum state, the use of high-shear emulsifier efficient, rapid and evenly distributed one phase or multiple phase to another phase, and each phase under normal circumstances (such as oil and water phase) are mutually exclusive.

Specification of the Vacuum Emulsifier:

|

1.1

|

Volume

|

Overall volume:350L;Working Volume:300L

|

|

1.2

|

Heating

|

Electric heating

|

|

1.3

|

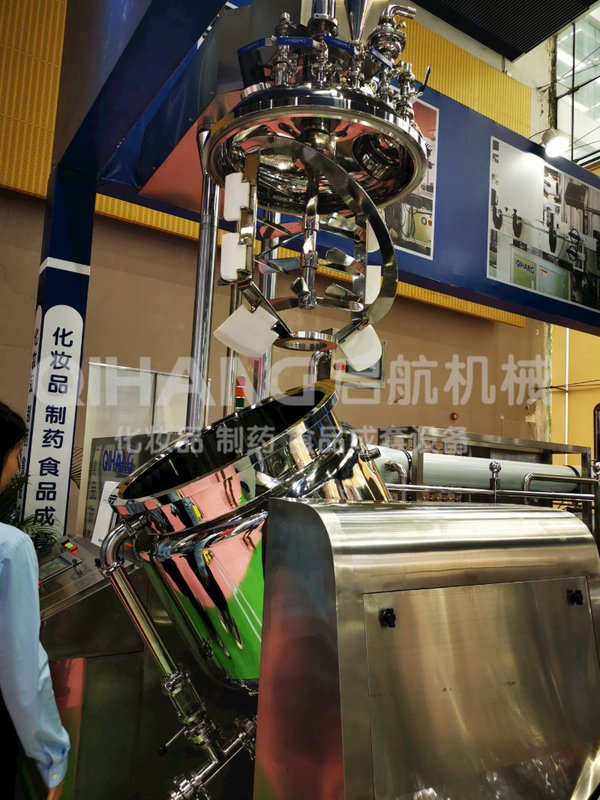

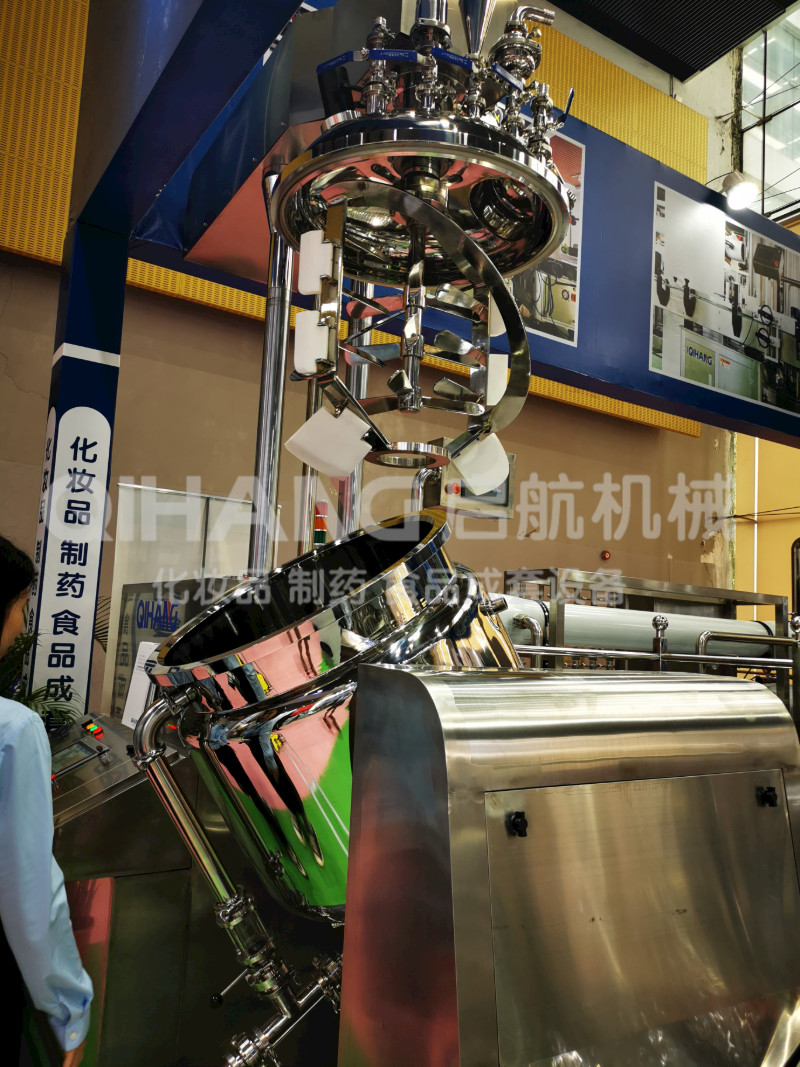

Basic Structure

|

Three layers,the cover can be lifting ,dumping system,the blender is bidirectional,

Top homogenizing;water cooling - heating coat,Insulation coat

|

|

1.4

|

Tank

|

Material contact later:SUS316L;Thickness:6mm; Jacket 6mm; Outer:SUS304,

Thickness:2.5mm

|

|

1.5

|

Cover

|

Material filter,Vacuum Pressure meter,Vacuum Exhaust Valve,Vacuum Port,

sight glass light,Vision window,inlet, sight glass with wiper and bulb, rotary

CIP heads, 10 liters hopper;Vacuum water pump unit;

|

|

1.6

|

agitator

|

scraped

|

|

Stirring coefficiency:

|

Stirrer motor:2.2KW,Speed:0~63R/M;

|

|

1.7

|

Homogeneous Way

|

Installation,internal circulation;

|

|

Homogeneous

coefficiency

|

Motor Power 7.5KW,Rotating speed 0-3600R/M

|

|

Processing

|

Rotor and Stator in Wire cutting,assembled after polishing

|

|

1.8

|

sealing

|

Adopting burgmann Machinery Seal,Japan NSK Rolling Bearing;

|

|

1.9

|

polishing

|

In&outside hygiene grades,conforming GMP standard

|

Feature of the Vacuum Emulsifier:

1. high sanitary standard manufacturing

2. internal surface mirror polished

3. agitation group consisting of two slow agitators and one fast agitator

4. double speed slow agitators(stepless speed variation as optional)

5. double speed fast agitators(stepless speed variation as optional)

6. mechanical seal of agitation groups

7. lifting cover system

8. tilting vessel

9. body and agitators made of SS AISI 316L

10. internal pressurization for discharge and inertization

11. SS AISI 304jacket

12. cover for thermal insulation made of SS tank in tank

13. vacuum group

14. heating station

15. sterilizing filter installed on the vacuum-breaking device

16. cleaning balls

17. embedded CIP group

18. product temperature check by means of Pt 100 probe,special sheath ,close to the side

19. buttons or PLC controlled process functions

20. electronic weighing system..

Siemens motor:

- Higher efficiency levels reduce energy consumption and directly enable users to save costs.

- The higher protection level (IP55) ensures safe and reliable use by customers.

Delta inverter:

- High energy-saving machine efficiency

- Efficient input and output power factor

- Highly flexible expansion method

- Low overall investment and maintenance costs

High shear homogenization:

- High uniformity, good polishing, energy saving, stable operation

- Speed of fast homogenizing stirrer:0-3500r/min (frequency conversion speed regulation)

Mixing part (Material: SUS316, GMP standard):

- Speed: slow wall scraping stirrer speed: 0-63r/min (frequency conversion speed regulation)

- Siemens motor + reducer provide strong and stable power for mixer, panasonic brand frequency inverter, PTFE material scrape blade.

Customer Reviews:

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!